Bead mills, grinding and dispersing equipment, are important and widely used in 40+ fields, such as battery materials, new nanomaterials, 5G semiconductor materials, etc. During application or production, the service life of the bead mill becomes a concern for most users. For example, can the bead mill operate for a long time? What is the longest running time in continuous operation mode? Does long-term use affect the service life of bead mills?

The continuous operation time of a bead mill depends largely on several factors, such as the working environment, the types of materials of the various components in the bead mill, and the design of the structure. Daily maintenance of the bead mill is necessary to ensure its excellent working condition. Make sure you follow the correct specifications in the instruction manual. Based on the above two basic conditions, the bead mill can operate stably and continuously for a long time. Many high-quality bead mills can work continuously for 24 hours for a few days, keeping them efficient and stable without any problems.

Here we come to the details about what ultimately determines the service time of the bead mill.

1. Frequency of use of the bead mill

Even with regular maintenance, the bead mill will eventually stop working beyond its running time. It is unlikely to last indefinitely and will inevitably stop running. The service life of bead mills that are frequently used is shorter than that of those with low frequency of use. Therefore, strategically scheduling the frequency of use of the bead mill and managing grinding tasks extend the service life of the bead mill. Avoiding useless idling and inefficient running of the bead mill as much as possible also helps.

2. Regular cleaning and maintenance

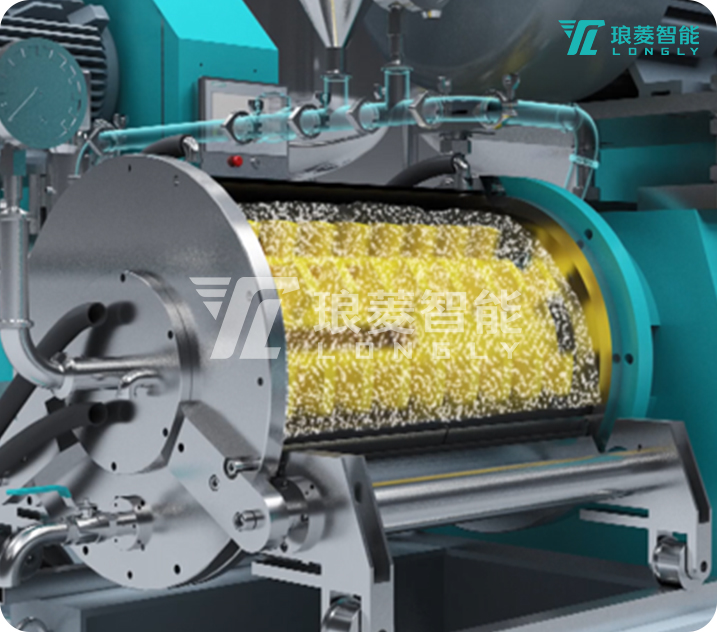

Inevitably, solid particles in the slurry can agglomerate and accumulate inside the agitator bead mill as the grinding time passes. If it is not cleaned in time, the agglomeration sediments and the screen and discharge port may clog, so the discharge speed may become slow. In the most severe cases, the bead mill will be damaged.

At the same time, the working intensity of the bead mill also needs to be considered. The durability of bead mills varies from different working intensities. If running for a long time under high working intensity, the bead mill will shorten the service time. When there is a need for long-term high-intensity grinding, the type with good quality, high durability, and easy maintenance is recommended.

3. Components of the bead mill and their performance

The components of the bead mill are also related to the life of the bead mill, especially some core or basic parts. For example, leakage of the mechanical seal will stop the function of the bead mill, greatly reducing the service life and viable use time. The quality of the motor, including its driving efficiency and operating life, are also crucial aspects that need to be fully evaluated.