As Lithium batteries and new energy are becoming a hot topic in society nowadays, many countries and regions are committed to the R&D and production of lithium batteries. Our country China took it seriously which has also received globally remarkable achievements.

When talking about the lithium batteries, it comes to the conductive agent carbon nanotubes. A certain amount of conductive material is usually added during battery production to ensure the electrode has good charging and discharging performance. It reduces the contact resistance of the electrode and accelerates the movement of electrons and lithium ions from the electrode, thereby improving the charging and discharging efficiency.

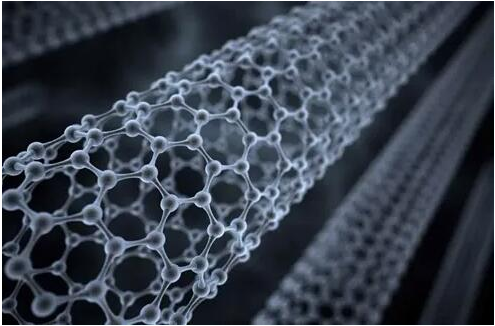

Carbon nanotubes are a one-dimensional quantum material with a special structure, whose radial is nanometer-level, axial is micrometer-level, and both ends are almost sealed. They are coaxial circular tubes mainly composed of multi-layer hexagonal carbon atoms. The distance between layers is fixed, about 0.34nm, and the diameter is generally 2~20nm. As a new material, carbon nanotubes have shown great application potential in many fields due to their excellent electrical, mechanical, chemical, and other properties since their discovery.

As important auxiliary materials for lithium-ion batteries, carbon nanotubes do not directly participate in electrochemical reactions. Although the conductive agent accounts for a small proportion of the battery, it greatly affects the performance of lithium-ion batteries. The proper amount of the conductive agents can improve battery cycle performance, capacity utilization, etc.

Carbon nanotubes as the conductive agents accelerate the movement of the free electrons and increase electrical conductivity, collecting the micro-current between active materials and between active materials and current collectors. Secondly, it increases the movement rate of lithium ions by promoting the infiltration of electrolytes into the electrode thereby improving the charge and discharge efficiency of the electrode as well as the service life of the lithium battery.

Carbon nanotubes and graphene are the two nanomaterials with the most outstanding performance in conductive agents, mainly supplied as dispersions (slurry). Usually, it will use the bead mills to produce the carbon nanotubes. Bead mills are used for wet grinding on chemical liquid products, roughly divided into horizontal, basket, vertical bead mills, etc. It consists of the machine frame, a grinding cylinder, an agitator disk (paddle), grinding media, a motor, and a feeding pump that controls the feeding speed.