The mechanical seal is a significant core component of the bead mill. Its performance directly affects the mill's service life and grinding performance. A properly installed, reliable, well-sealed mechanical seal is essential to a high-quality bead mill. So how is the mechanical seal of the bead mill installed and replaced? What procedures should be followed? Let's take a look.

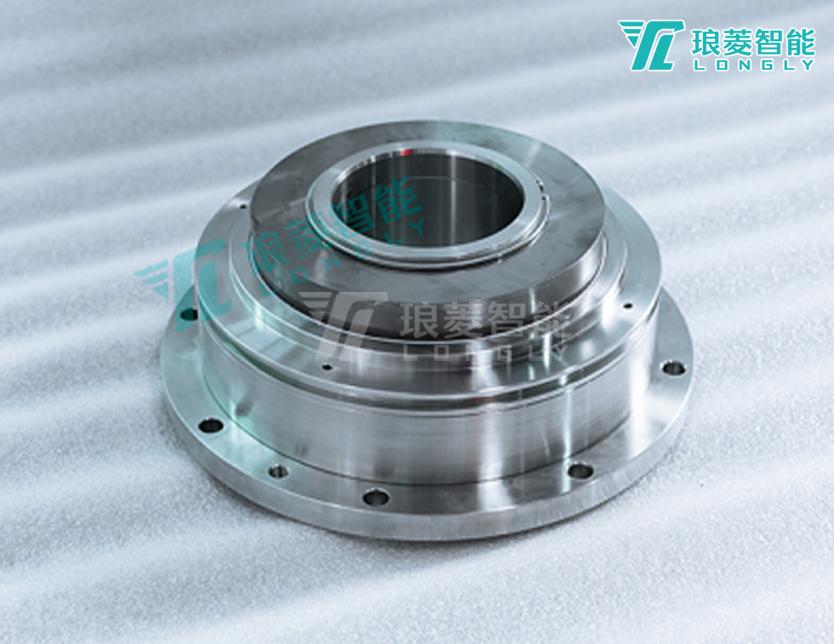

Before replacing and installing the mechanical seal of the bead mill, you should first familiarize yourself with the mechanical seal diagram, to understand its structure and basic composition. This is the key and prerequisite for successfully replacing the mechanical seal.

After removing the inner cylinder, we carefully remove the components of the dispersion plate and clean the removed parts to ensure subsequent stability. Then remove the screen and clean the core bearing with a cleaning solvent. Do not forget to remove the front cover of the cylinder and the discharge cover.

Next, remove the two elastic rubber hoses and the discharge plate. Then slowly remove the sealing ring to avoid collision due to gravity for subsequent sealing performance. Carefully clean all the spare parts removed, including the gasket and bearing protectors, especially the moving and static rings that need cleaning to prevent dust from affecting the operation process and grinding.

After disassembly, the new mechanical seal needs to be reinstalled. During this step, place the spring in the small hole of the bearing protector and glue it with a little grease to keep it in the correct position. Be sure to install the gasket and O-ring on the shaft and the moving ring to get the gasket against the small spring. Check that the O-ring is installed correctly and that the bearing protector pin passes through the gasket and the moving ring seat hole. Then install the tray and check that it is in the correct position to connect the rubber tube. Next, install the front of the cylinder on the frame base. Then place the screen and dispersion disc on the shaft. Turn the shaft by hand and maintain a 0.4mm gap between the inner and outer scrapers to ensure grinding performance. Finally, install the cylinder and make sure the lubricant is in the correct position.

The installation of the mechanical seal is essential when using the bead mill. Regular maintenance with proper methods for the mechanical seal is necessary, which also helps extend the service life of the bead mill. Once the mechanical seal coolant leaks, the staff should be able to replace the mechanical seal or repair it to ensure long-term normal production.