With the aging global population and increasing economic growth, the scale of the pharmaceutical market has been expanded, driven by the growing demand for medical health. However, the pharmaceutical industry faces challenges. From the serious absence of high-end biopharmaceutical equipment to the weak innovation, it all restricts the development of the sector and corporate costs.

The pharmaceutical industry, an important part of our economy, combines traditional with new high-tech. How to meet the various pharmaceutical production requirements with high efficiency, innovative technology, high automation, and multi-function equipment that conducted the Good Manufacturing Practice (GMP), is a pressing priority for pharmaceutical enterprises.

In response to the difficulties currently faced by the pharmaceutical industry, LONGLY has launched three solutions for global customers and taken the opportunity of the China International Pharmaceutical Machinery Exposition(CIPM) to display the high-end equipment: vacuum feeder, CIP and SIP bead mill, high-pressure homogenizer, spray dryer, and other star products, which brought a feast of equipment and technology to domestic and foreign visitors.

Solution 1: Conveying System Optimization

The LONGLY conveying system can be customized to accurately match the conveying equipment, aiming at the diversity of pharmaceutical materials, such as fineness, temperature sensitivity, and active ingredients.

In the conveying system, the vacuum feeding unit has strong adaptability and high conveying efficiency. With precision structure using materials strictly selected combined with exclusive aerodynamic technology, it is accessible to smooth conveying and reduces the loss and deterioration of materials during the conveying. At the same time, the intelligent control system provides accurate control of conveying speed, volume, pressure, and other parameters to ensure stability and safety.

Solution 2: Grinding and Homogenization System Optimization

The active particles in pharmaceuticals at ultrafine nano level can effectively increase the rate of utilization and absorption. LONGLY grinding and homogenization systems can fully adapt the grinding, homogenization, and dispersion of professional pharmaceutical companies, helping develop new products, meet compliance requirements, improve quality, enhance stability, and other needs.

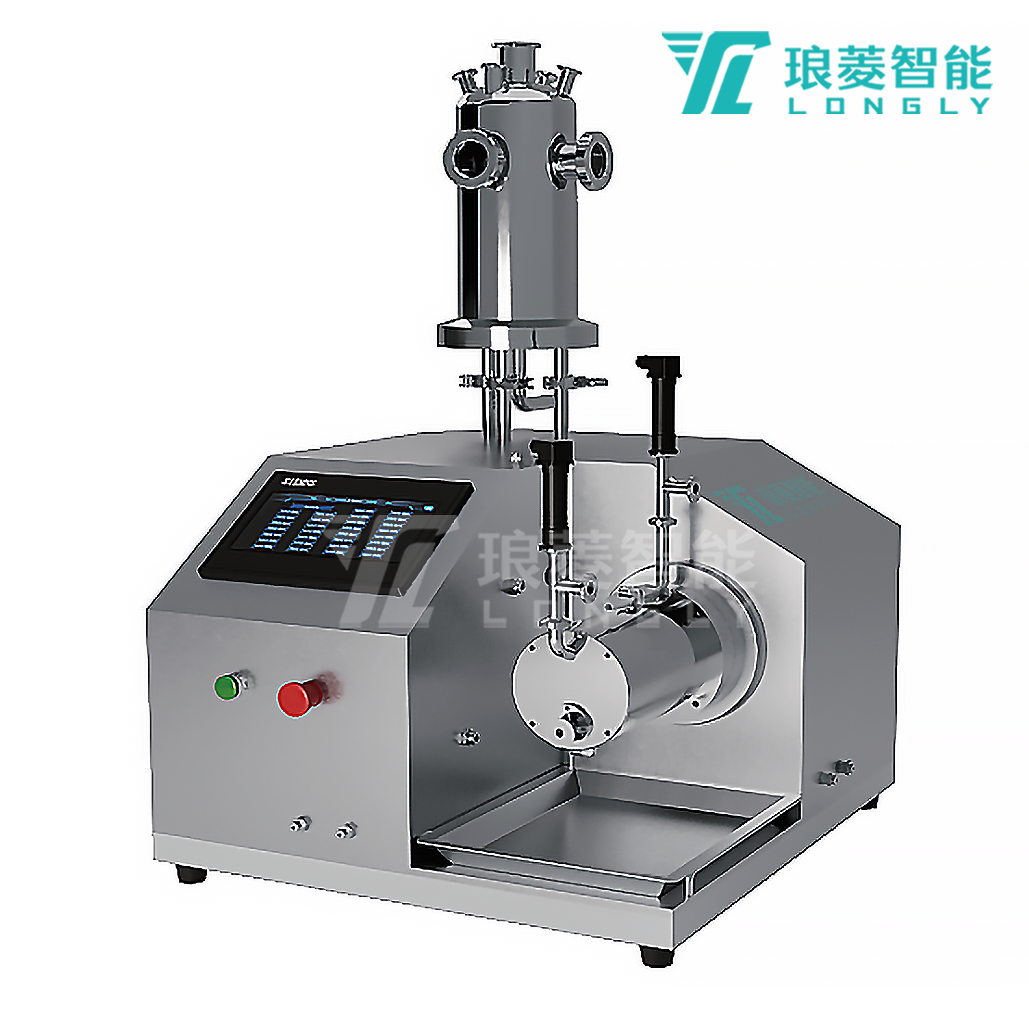

LONGLY cleaning and sterilizing in-place bead mills, specially designed for pharmaceuticals and food enterprises, are compatible with laboratory requirements for various solvent formula verification and testing medicine performance. The CIP/SIP is flexible for aseptic research development, testing, and production. The grinding chambers are easily replaceable allowing it to scale up accurately from small lab trials to large-scale production.

▲Lab Bead Mill designed for Pharmaceuticals

Vertical bead mill LS-Q can high efficiently reach narrow particle size distribution. Centrifugal non-screen separation has a wide appliance of zirconium balls as low as 0.05mm. Double-check valves prevent ultrafine grinding media backflow. The special machine seal makes the vertical bead mill leakage-free, stable, and reliable with low energy consumption.

High-pressure Homogenizer, self-patented by LONGLY, has become a powerful assistant for biopharmaceutical and food companies due to its stable and controllable homogenization pressure and high shear force. The Homogenizing pressure from max. 2000 bar to an ambient pressure can be adjusted to achieve the desired particle size and improve the uniformity and stability of liquid mixing. So can the circulation times. Our practical technology, unique design, and high-quality manufacturing can provide homogenizers for laboratory, pilot, and production lines.

LONGLY can provide customized grinding and homogenizing equipment that significantly improves the efficiency of pharmaceutical enterprises from raw material storage to grinding. Thanks to our advanced intelligent monitoring systems, the equipment's running status, including key parameters such as feeding and discharging, rotation speed, and temperature, can be monitored in real-time.

Solution 3: Spray Drying System Optimization

Regarding our spray drying system, we have specially set the sensors for particle size analysis and drying degree analysis at each key stage to monitor and remove unqualified particles in time and then realize automatically closed transportation to the next process.

The entire production is highly automated, and data can be traceable throughout. More importantly, the risks brought by manual operation for sterile production will also be reduced accordingly, as fully enclosed continuous production effectively improves the quality of the final product.

One-stop Solution for Automatic Production Line Aiming at Industry Challenges

In terms of automated production lines, LONGLY’s rich experience in 380+ successful turnkey projects allows us to provide digital, standardized, and intelligent one-stop solutions tailored to customers, covering feeding, precise metering and batching, premixing and dispersion, grinding, filtration, automatic filling, and remote control.

From scheme design to project implementation, LONGLY's team adheres to professional, efficient, and responsible services to provide serial solutions for the pharmaceutical industry, helping the enterprise improve production efficiency, product quality, and core competitiveness.