There are three types of separation systems or discharge methods for bead mills: static screen separation, dynamic screen separation, and centrifugal separation (non-screen separation), each plays an important role in the grinding performance. Choosing the appropriate separation method mainly depends on the characteristics and viscosity of the grinding material to achieve the best grinding performance. Here it is.

1. Static Screen Separation

Static screen separation gets larger particles separated from finer ones when the slurry passes through a stationary screen or sieve, which is simple. It relies on gravity and the natural flow of the slurry.

The advantages of using static discharge:

1. Stationary screen: The screen does not move as fixed in place.

2. Gravity-Based: when the slurry flows through the screen, the finer particles pass through the screen with larger particles retained.

3. Simple and cost-effective: easy to maintain, widely applicable.

Small zirconium beads ranging from 0.3mm to 2.0mm are applicable. It is especially suitable for those in medium and low viscosity. The available types of bead mills are NT-V, LDM-D, LSM-B.

▲Mass Production Pin-Type Nano Bead Mill NT-V Series

2. Dynamic Screen Separation

The dynamic screening separation uses the moving or vibrating screen to facilitate the separation process. It helps prevent clogging and improves separation efficiency. The advantages of using dynamic screen separation:

1. Moving screen: The screen vibrates or rotates to enhance the separation.

2. Dynamic separation: Dynamic movement helps remove particles that may clog the screen.

3. Higher efficiency: The separation efficiency is higher than static screen separation.

4. Suitable for viscous slurry: especially for slurry with high viscosity or slurry that is easy to agglomerate.

The dynamic discharging is suitable for medium and high-viscosity materials. The available types of bead mills are LDM-C, LDM-G, and those with desired particle size at μm scale.

▲Pin Type Micron Bead Mill LDM-C Series

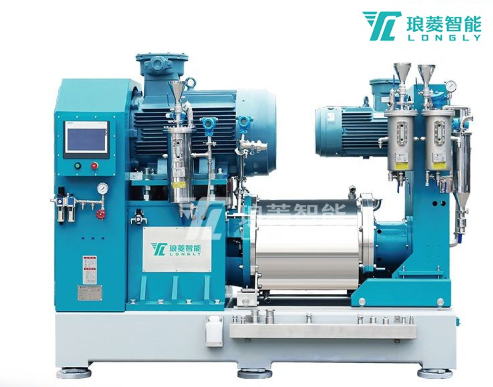

3. Centrifugal Separation (Non-Screen)

The centrifugal separation in the bead mill adopts the centrifugal separation principle without a screen using an independent drive motor. When the bead mill is running, most of the grinding media zirconium beads get distributed inside the grinding chamber under the centrifugal force of the separator and move accordingly in the same direction as the grinding slurry. Only a small amount of zirconium beads and materials rotate around the separator.

Under high-speed rotation, the centrifugal force generated by the separator on the zirconium beads is larger than the pressure generated by the pump on the grinding beads, making the zirconium beads stay in the grinding chamber. At the same time, the centrifugal force generated by the separator on the material is less than the pressure generated by the pump on the grinding material, thereby forcing the material to flow through the separator. The grinding cylinder adopts silicon carbide material with good wear resistance and thermal conductivity, which allows wilder application.

▲Dual-Power Centrifugal Nano Bead Mill NT-VS Series

The advantages of using the centrifugal separation (without screen):

1. Centrifugal force: The particles are separated based on their density and size under high-speed rotation.

2. No screen: no screen clogging and easy for maintenance.

3. High precision: It allows finer separation especially ideal for those in high purity and consistency.

4. Fineness control: suitable for grinding requires precise control of particle size distribution.

The centrifugal separation (non-screen) can use smaller zirconium beads from the smallest 0.03mm to 0.3mm. The available types of bead mills are horizontal dual-power NT-VS, vertical dual-power LS-Q, vertical LS-K, and the other ultra-fine nano-grinding and dispersion for low viscosity.

In short, how to select the separation in the bead mills depends on the specific requirements of the grinding process, the characteristics of the material being processed, and the desired grinding performance. Bead mills, an important grinding equipment, are crucial in material processing and industrial production. By reasonably selecting various discharge methods, it can improve the efficiency and quality of grinding, and fully meet production needs.

Therefore, it is necessary to fully understand the different separation methods and their characteristics for better application according to the actual demands, as it ensures the smooth progress of the process and the improvement of product quality.