Suspension concentrate (SC), an important pesticide formulation, is one of the four environmentally friendly formulations recommended by the Food and Agriculture Organization (FAO). As pesticide formulations develop towards safety, environmental protection, and water-based, suspension concentrate (SC) will be the form with wider application of pesticides. Suspension concentrates have good dispersibility with highly suspended solid active ingredients that strongly adhere to the plant surface and resist rain erosion. Compared to wettable powders, the efficacy is more significant and durable.

Suspension concentrate (SC), refers to formulations with insoluble solid active ingredients or drugs (normally at high concentrations), less than 4 microns, dispersed in water. Unlike wettable powder (WP), SC does not waste additional powders spreading around, preventing flammable and explosive problems in some way. It is safer and more environmentally friendly. The small packaging volume thanks to the high bioactivity with a large specific gravity in small particles makes it stand out in water-based pesticide formulations.

The solid particle size is around 0.1 to 3 μm and its high suspension rate provides strong efficacy. SC is a non-powder formulation with no hazardous organic solvents and is therefore considered low in volatility and toxicity. It is safe for storage and transport and can be sprayed by aircraft. However, additives such as stabilizers and antifreeze agents are needed to prevent decomposition, precipitation, freezing, etc.

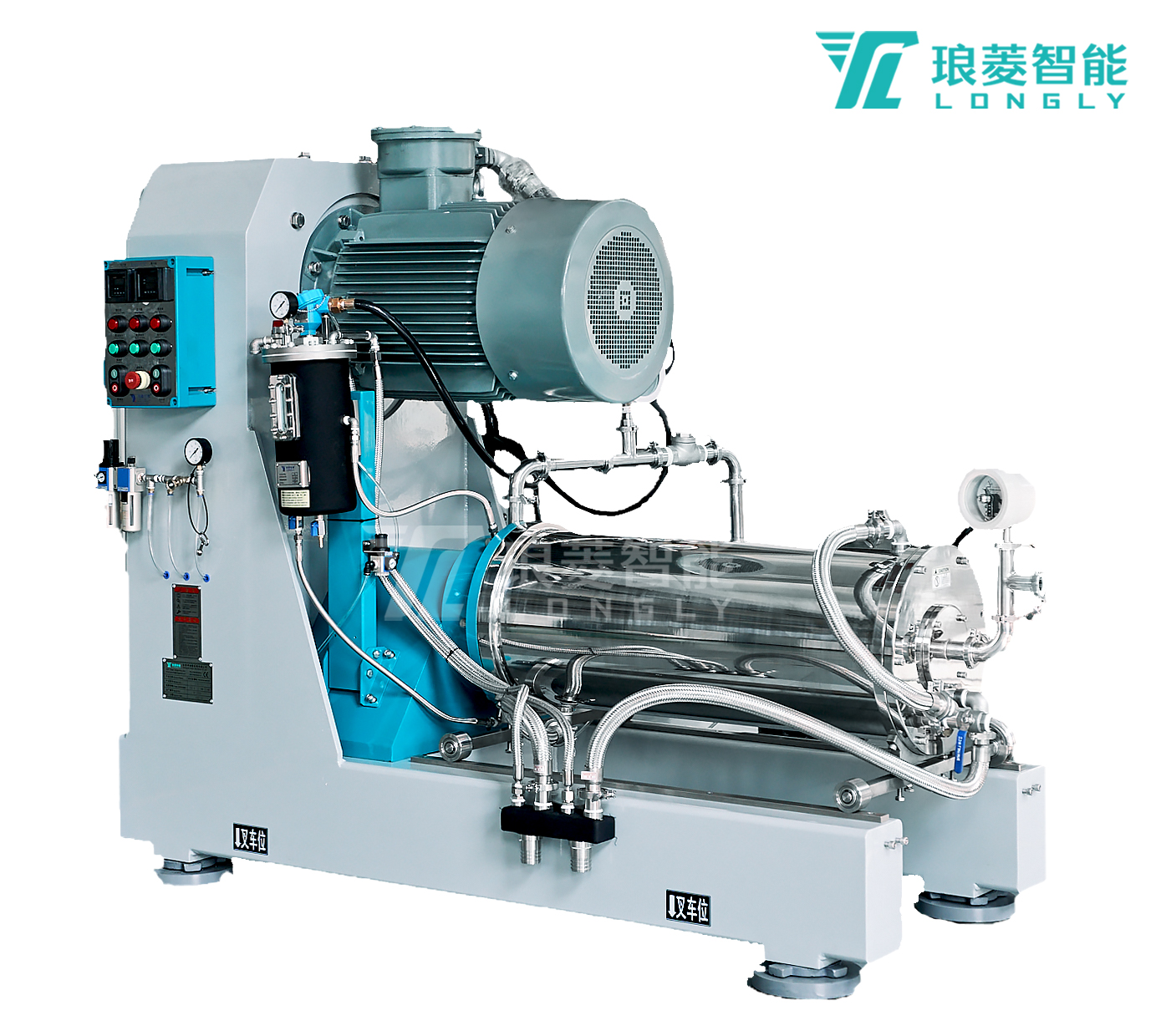

The LONGLY bead mill LDM-D series is an excellent choice for grinding solid active ingredients to create pesticide suspension concentrate. It provides micron grinding with particles that discharge less than 15 microns. It is also common in the dispersion and grinding of chemical materials in fields such as coating, ink, etc. Bead mill LDM-D adopts an upgraded pin-type grinding structure and a high-power system, ensuring sufficient rotation speed for grinding. The patented dynamic screen used in separation makes the bead mill LDM-D available using small zirconium beads and large flow without clogging. The bead mill can be made of polyurethane, ceramics, wear-resistant steel, and tungsten carbide to suit different grinding needs.

Bead mills, also known as sand mills, provide wet grinding to the SC by ultimating the rotation of the grinding beads (usually wear-resistant, such as zirconium beads) inside a closed chamber. A large amount of kinetic energy from the rotor driven by the motor acts on the zirconia beads to crush, impact, and shear the solid particles in the grinding slurry in the closed chamber. Bead mills are adaptable and advanced in grinding that can achieve continuous processing and discharging. The cooling section and automatic control system greatly improve grinding performance and production efficiency.

The grinding results of the bead mill are almost irreplaceable in some way. Faced with increasing competition in the powder market and fierce challenges in the quality of powder products, LONGLY has absorbed advanced technology to produce high-quality equipment that meets market demand. We strive to provide cost-effective grinding and dispersing equipment for base material manufacturers.