Under fierce competition and great change in the coatings industry, the CHINACOAT2024 was held grandly in Guangzhou on December 3, crowded with visitors. It is an event where you can see cutting-edge technologies and innovative achievements in coatings.

LONGLY Group attended with a quantity of advanced equipment for coatings and drew huge attention at booth number 3.1E13. The series of specialized, refined, special, and new high-end equipment on display accurately solved many problems and difficulties that coatings enterprises have faced for a long time.

When passing by our booth, what caught your eye was our Glasses-Free Dynamic 3D presentation. On the screen, various types of equipment, such as vertical and horizontal nano bead mills, large flow discs, and pin bead mills, are presented to the audience with realistic dynamic effects, full of mechanical technical charm and beauty. The precise internal structure is clear and visible.

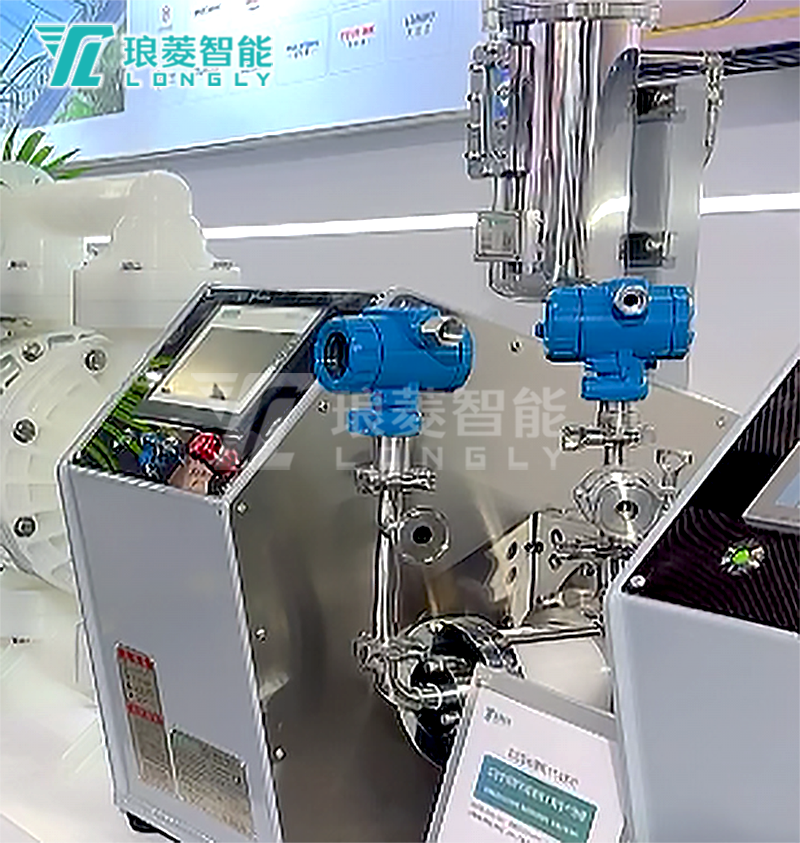

Surrounded are the above bead mills, among which the premiere vertical and horizontal bead mill NT-VE is undoubtedly the "champion" of high efficiency and high quality as it combines the advantage of horizontal grinding and vertical separating. For coating companies with small workshop layouts, the traditional type is limited in installation which may be poor connections. The bead mill NT-VE with such a unique design breaks the deadlock bringing amazing grinding performance and new possibilities to the industry.

▲Vertical and Horizontal Bead Mill NT-VE

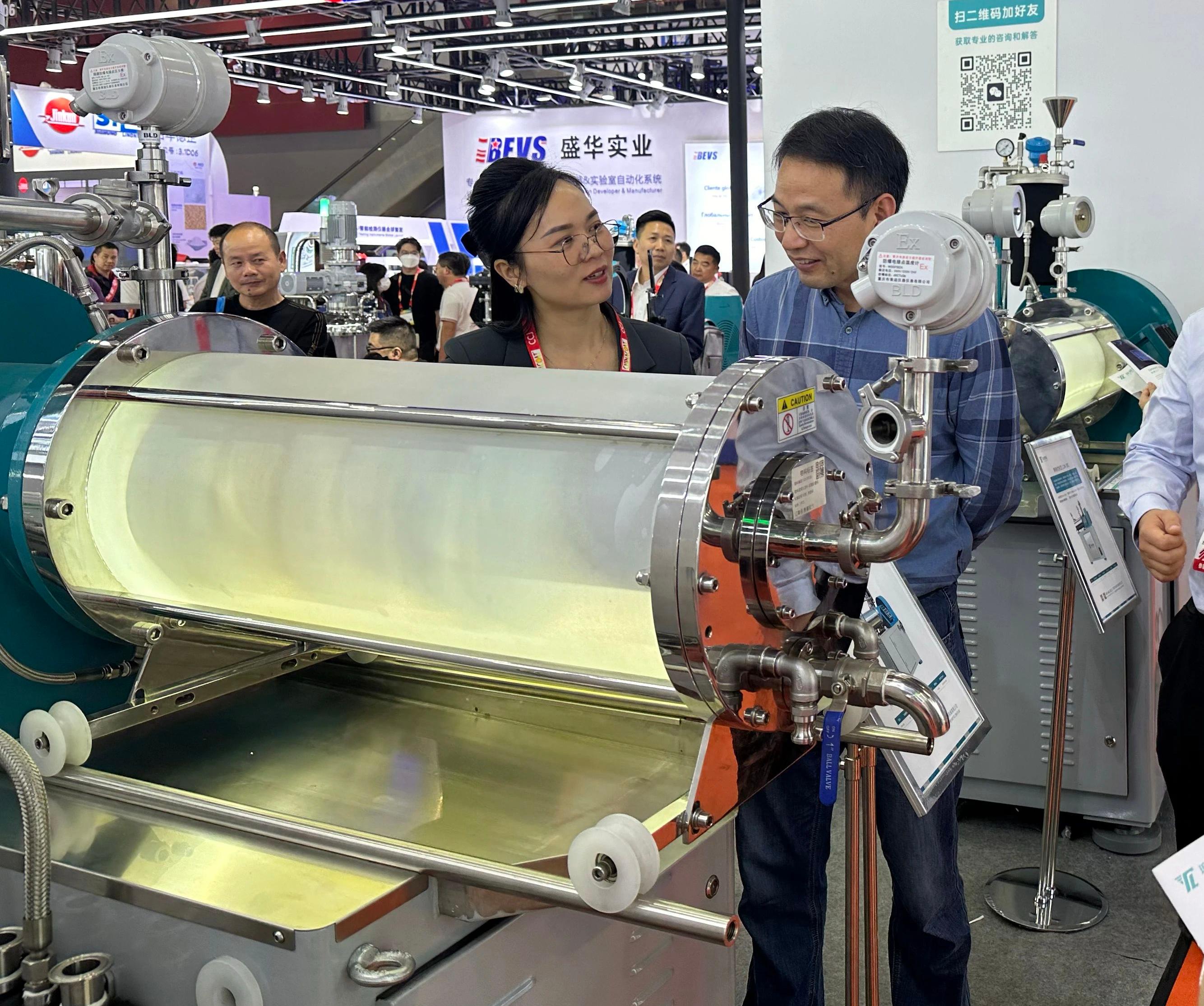

The laboratory bead mill, the grinding equipment, is mainly used for small-scale testing or R&D of coating. In the past, when the laboratory formulated new coatings, pigment particles milled by ordinary grinders were often uneven with wide particle size distribution due to poor precision and unstable temperature control, which seriously affected the purity and uniformity of coating.

▲ Laboratory Nano Bead Mill NT-V

Instead, the LONGLY laboratory bead mill NT-V series provides nano-level grinding thanks to its ultra-high-speed stability and temperature control accuracy so that the product from every experiment is full of color and fine in texture. It greatly shortens the new product development cycle. For colleges, universities, and research institutes, the grinding parameters can be flexibly adjusted to simulate different working conditions so researchers can easily explore new formulas.

At the same time, the exhibited ultra-high-speed multifunctional mixer that integrates emulsification and dispersion was on display as laboratory equipment. A variety of mixing heads are optional according to the needs. The rotation speed can reach up to 20,000r/min, varying depending on the mixing head. Also, with forward and reverse switching functions, it has a wide application in product development, raw materials testing, and formula verification. With the help of such powerful experimental equipment, academics in coating are no longer limited by equipment, laying a solid foundation for the innovation of coating technology.

▲Ultra-high-speed Multifunctional Mixer

On the industrial coating production line, time is money. The pin-type bead mill, known as the "efficiency leader" of large-scale mass production of coatings, overcomes the problems caused by conventional bead mills in low grinding efficiency, clogging, and frequent shutdowns. With its upgraded innovative pin structure, the third-generation pin-type bead mill can severely crush pigment agglomerates quickly to reach the ideal precise fineness. The patented dynamic screen system allows large flow separating without blockage. The whole grinding process is full of efficiency and stability making the production capacity soar, so coating enterprises can easily cope with massive orders and seize the market opportunities.

The dry bead mill offers promising solutions for advancing research, development, and production in the powder coating industry. For powder coating, the raw materials are prone to absorb moisture and agglomerate, making conventional wet grinding ineffective and posing significant risks during storage and transportation. However, the LONGLY dry bead mill, accurately crushing and dispersing dry powder raw materials in a dry environment without water participation throughout the process, can provide uniform particles with stability far exceeding its peers. Such a closed grinding chamber prevents dust leakage, which is environmentally friendly and safe. It somehow broadens the coating company's product line.

▲Dry Bead Mill

The large-flow disc bead mill, common in large paint companies, can achieve massive throughput with the grinding disc and powerful power system. Apart from the bead mill, there on display is the online dispersion system that connects to the vacuum feeding system, to show the full process from feeding to dispersing in live. The deaerator equipment displayed contributes to the coating quality as once bubbles or air are dissolved into its liquid coating, it affects the coloring performance and durability. The deaerator or degassing equipment uses advanced vacuum technology and physical centrifugation to remove the dissolved air.

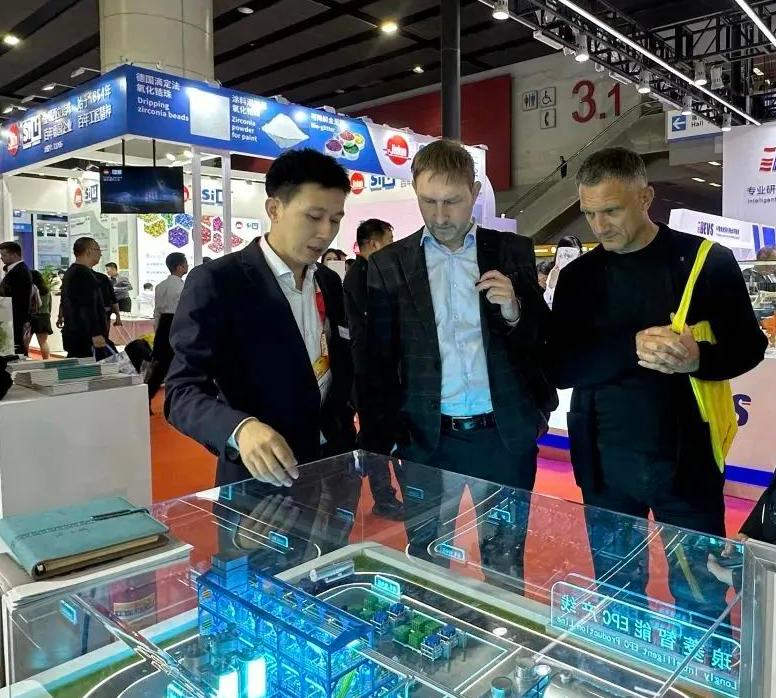

Moving to the EPC model, the one-to-one scaled-down model accurately presents the entire production line. One by one, the advanced equipment is placed in order according to a reasonable design. You can see the full production process directly from the front-end feeding to the back-end discharging. The realistic display attracts great attention. The miniature full-function batching platform debuted at this exhibition, was engineered by the LONGLY R&D team to realize the test on the logic program and verification of the control system in the production line, as the process from material storage to batching and metering is huge.

▲Miniature Full-function Batching Platform

During the three-day exhibition, the technical and purchasing managers of coatings companies gathered around these types of equipment, full of surprise and expectation. Some had in-depth discussions with the LONGLY professional technical team on operation details, equipment applications, and customized solutions. They also shared their experiences with experts, scholars, and corporate elites from different industry sectors.

CHINACOAT2024 is not only a leading platform for equipment display, but it is also a place where you can get knowledge, connections, and business opportunities. With the help of our LONGLY specialized, refined, special, and new high-end equipment, coatings companies will break through technical bottlenecks, resolve production problems, move towards high-quality development, and boost the entire industry to a new stage of efficiency, intelligence, and greenness.