Cleaning the screen in the separator to remove fouling and impurities on the screen is important to ensure the normal operation of the bead mill and the stability of the final product quality. The solid particles crushing during the grinding may generate impurities or fouling, especially when the bead mill runs continuously for a long time, which may clog the screen if there are many. Thus, regularly cleaning the screen of the bead mill is necessary. Two common methods for cleaning screens, one is mechanical cleaning and the other is chemical cleaning.

Mechanical cleaning usually uses a water gun or specific washing equipment to flush the fouling or impurities from the high-pressure water. It can quickly remove residues on the screen allowing materials to flow through it normally and improving the screening efficiency. The high-pressure water flow can penetrate fouling and remove it from the screen gaps. Compared with traditional manual hand cleaning, mechanical cleaning saves time and effort for better cleaning results.

Mechanical cleaning also reduces the potential risk of screen wear and damage. Traditional cleaning may require scrubbing the screen with a brush or other tools, which may cause wear and damage to the screen. The impact force from the high-pressure water flow creates less friction on the screen.

Chemical cleaning refers to adding cleaning agents or detergents into the cleaning solution and using the mixture to dissolve and remove the impurities through soaking and stirring. It is suitable for cleaning stubborn stains or fouling thoroughly to ensure cleanliness. The types of chemical cleaning agents are determined based on different cleaning needs because the cleaning agents consist of some powerful chemical components that can react with impurities or fouling.

During the cleaning, the screen is completely immersed in liquid, so that the cleaning agent can fully contact the impurities to accelerate the decomposition and removal. At the same time, through stirring, the cleaning agent contacts every corner thoroughly of the whole screen. This chemical cleaning stands out in cleaning the tiny impurities besides the visible fouling, and it is adaptable to various screens used in the industrial field, including filters and sieves. The screen by this cleaning method can be kept in a good state for its normal operation and service life.

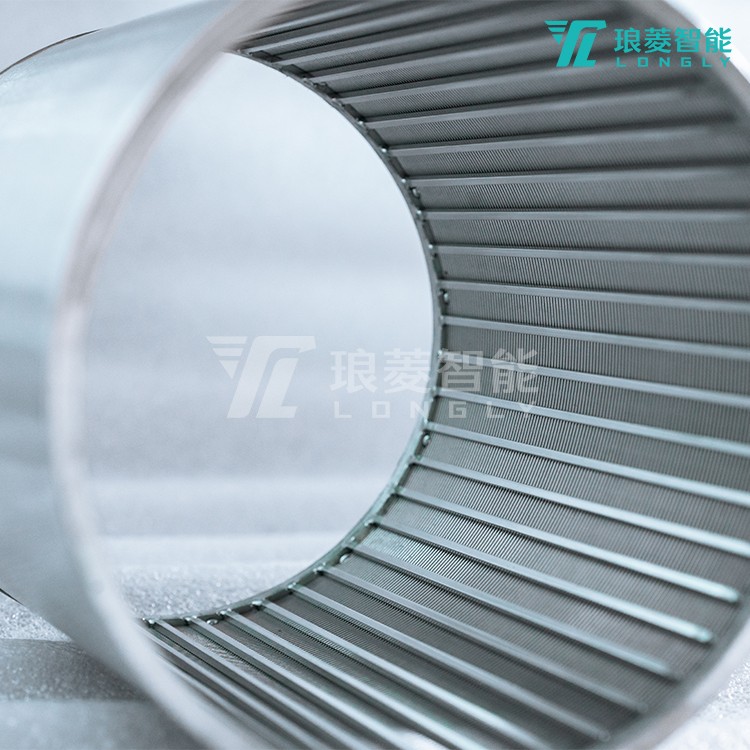

LONGLY bead mill has installed an ultrasonic anti-blocking device inside for the automatic cleaning function of the screen. Such a device greatly saves production time and efficiency with manual disassembly and cleaning reducing.

No matter which cleaning method is selected, mechanical or chemical, it is subject to the specific situation. What needs to pay attention to is the safety measures, to avoid damage to equipment and injury to users. Regular screen cleaning helps maintain the normal operation of the bead mill, improve production efficiency, and extend the service life.